[EN-US] GORE-TEX PYRAD® Products - Arc-Rated Garments

GORE-TEX_PYRAD_2L_03_24.pdf

Workwear

GORE-TEX PYRAD®

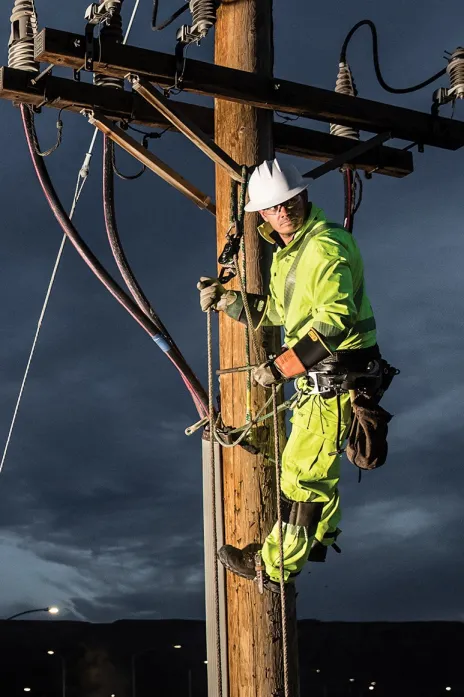

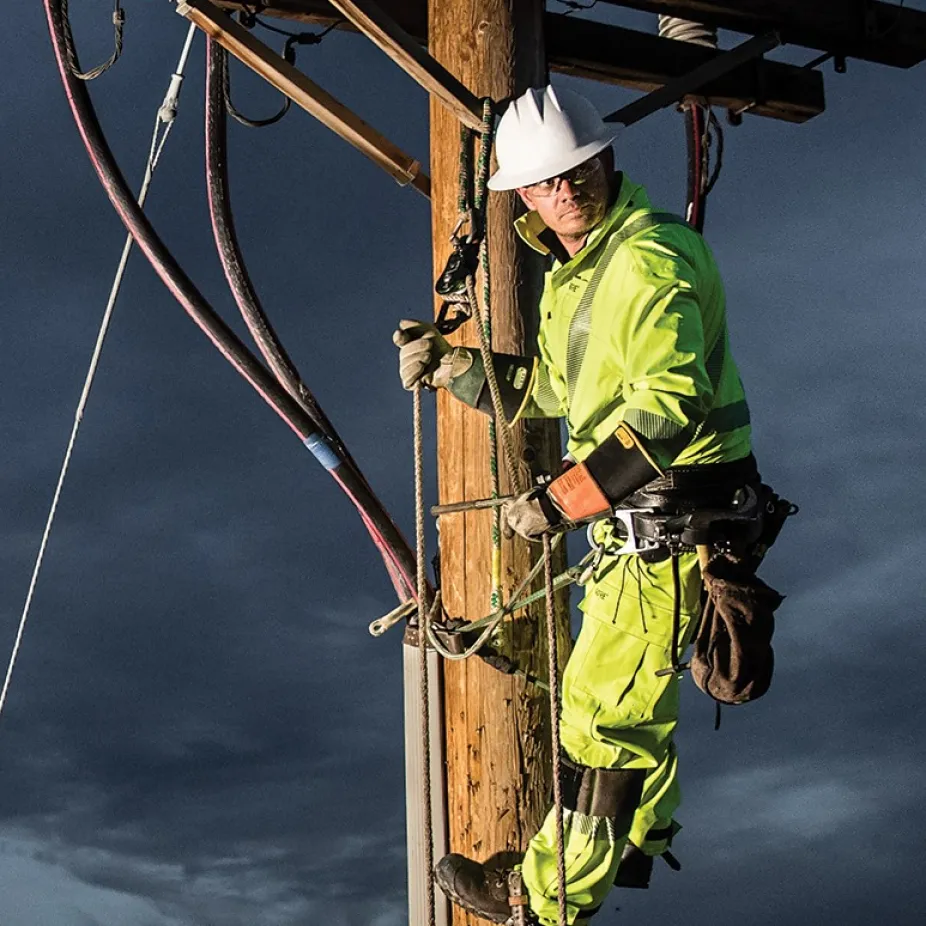

ARC RATED GORE-TEX PYRAD® GARMENTS for Outdoor Electrical Workers

GORE-TEX_PYRAD_2L_03_24.pdf

Workwear

GORE-TEX PYRAD®

ARC RATED GORE-TEX PYRAD® GARMENTS for Outdoor Electrical Workers

GORE-TEX_PYRAD_2L_03_24.pdf

Workwear

GORE-TEX PYRAD®

ARC RATED GORE-TEX PYRAD® GARMENTS for Outdoor Electrical Workers

GORE-TEX_PYRAD_2L_03_24.pdf

Workwear

GORE-TEX PYRAD®

ARC RATED GORE-TEX PYRAD® GARMENTS for Outdoor Electrical Workers

Elkton, Maryland, February 2, 2016 – W. L. Gore & Associates, Inc., has introduced a new line of protective fabrics that deliver the best combination of broad protection, comfort, and durability for arc-flash rated, foul-weather protection. From the inventors of GORE-TEX fabric technology, GORE® PYRAD® fabric enables line technicians to work for longer periods without being distracted by discomfort in cold or wet conditions.

GORE® PYRAD® fabric delivers protection beyond ASTM F1891 requirements. Its revolutionary self-extinguishing properties enable the fabric to maintain its physical integrity even after direct exposure to flame. Rainwear made with this fabric also meets the requirements for ANSI 107 hi-visibility, improving linemen’s safety without having to wear additional vests while responding to service calls in high-traffic areas.

GORE® PYRAD® fabric has been proven in wear trials to deliver durable waterproof, windproof, and breathable protection. The fabric’s highly breathable and lightweight construction helps improve comfort in two ways. First, it decreases sweat buildup, keeping the linemen cooler in warm conditions and warmer in cool conditions. And, second, it decreases water pickup, allowing it to dry faster, which reduces that uncomfortable clammy feeling from reusing damp foul weather gear multiple times during a shift. Available in rainwear from leading manufacturers, GORE® PYRAD® fabrics have been storm-shower tested and field proven to ensure that line technicians stay dry and comfortable regardless of the weather.

According to Mark Williams, Product Specialist, “When we are developing a new product at Gore, we work closely with end users to learn about their unique needs and the challenges they face in the environments where they work. Line technicians need to be able to focus on restoring customer service regardless of the weather conditions, so they need outerwear that is comfortable and provides the necessary arc-flash protection. Drawing from our years of experience with breathable protective fabrics, we engineered this new fabric to deliver the broad protection linemen aren’t getting today, while adding the comfort they deserve.” For more information, visit www.GoreProtectiveFabrics.com/Utilities or call 800.431.GORE (4673).

About W. L. Gore & Associates, Inc.

Gore is a technology-driven company focused on discovery and product innovation. Well known for waterproof, breathable GORE-TEX fabric, the company’s portfolio includes everything from high-performance fabrics and implantable medical devices to industrial manufacturing components and aerospace electronics. Founded in 1958 and headquartered in Newark, Delaware, Gore employs more than 10,000 associates worldwide. Gore is one of a select few companies to appear on all of the U.S. “100 Best Companies to Work For” lists since the rankings debuted in 1984.The company also appears regularly on similar lists around the world. Learn more at www.gore.com.

# # # #

Media Contact:

Marie Y. Smith

Public Relations Consultant

302.994.0117

G10274_GT PYRAD_Breathability Sell Sheet_4 pager_1-28A_WEB.pdf

Workwear

GORE-TEX PYRAD®

ARC RATED GORE-TEX PYRAD® GARMENTS for Outdoor Electrical Workers

G10274_GT PYRAD_Breathability Sell Sheet_4 pager_1-28A_WEB.pdf

Workwear

GORE-TEX PYRAD®

ARC RATED GORE-TEX PYRAD® GARMENTS for Outdoor Electrical Workers

PYRAD® fabric technology by GORE-TEX LABS blocks convective heat flow during arc exposure and stops flame propagation by forming a carbonaceous char with the textile.

When wet or dry, these garments are up to 20% lighter than other garments with category 3 arc protection, allowing the wearers to work outside for extended periods during heavy rain.

As breathability is key for an improved comfort and leads to an increased wearer acceptance, GORE-TEX PYRAD® fabrics are highly breathable and avoid build up of moisture from inside.

Arc rated GORE-TEX PYRAD® garments are durably waterproof and keep the wearer dry and comfortable when working long hours outdoors in heavy rain.

Arc rated GORE-TEX PYRAD® garments are durably waterproof and reliably protect electrical workers against the thermal hazards of an electric arc. They stay lightweight and comfortable even when wet.

This technology is available in two different laminates, both of which are Cat 3 arc rated (30 cal / cm2):

Upon arc exposure, the arc rated GORE-TEX PYRAD® fabric reduces convective heat flow and stops flames or damage from an arc flash by forming a carbonaceous char with the fabric. Heat transfer is reduced, the physical integrity of the fabric is maintained effectively for reduced heat transfer to the skin.

3-layer laminate:

ASTM F1891-19 | NFPA 70E-2018: ARC & FLAME RESISTANT RAINWEAR

ASTM F2733: FLAME RESISTANT RAINWEAR FOR PROTECTION AGAINST FLAME HAZARD

Contact garment manufactuers for jacket and bib styles that are compliant to this standard

ANSI/ISEA 107 / CSA Z96: HIGH VISIBILITY

ASTM F1868 | ASTM F1868: EVAPORATIVE RESISTANT (Ret) – BREATHABILITY

2-layer laminate:

ASTM F1891 - NFPA 70E (USA) & CSA Z462 (CAN): ARC AND FLAME RESISTANT RAINWEAR

ASTM F1959: ARC RATING OF MATERIALS FOR CLOTHING – CAT 3 (ATPV ≥ 30 cal/cm²)

ASTM F2733: FLAME RESITANT RAINWEAR FOR PROTECTION AGAINST FLAME HAZARD

Contact garment manufacturers for jacket and bib styles that are compliant to this standard.

ANSI/ISEA 107 / CSA Z96: HIGH VISBILITY- YELLOW & ORANGE

ASTM F1868 / ISO 11092: EVAPORATIVE RESISTANT (Ret) – BREATHABILITY

OTHER FEATURES:

OEKO-TEX® STANDARD 100: Supplement for “PPE and PPE material”- Annex 4 product class II Certified.

CALIFORNIA PROP 65 Compliant